Click the button to start reading

Taking Your Business to the Next Level with Continuous Improvement

Does your business feel stuck in a rut? Are your growth charts beginning to look like EKG readings from a narcoleptic sloth? If that’s the case, we might have just the jumpstart you need. We’re about to explore an approach that keeps your business not just surviving but thriving.

Continuous Improvement: Your Secret Weapon to Business Success

What is Continuous Improvement and Why Should You Care?

Continuous improvement might sound like one of those fancy corporate buzzwords that get thrown around in boardroom meetings. But here’s the deal—it’s a lot more than that. It’s like a secret sauce for your business.

At its core, continuous improvement is a long-term business strategy aimed at boosting your organization’s efficiency, productivity, and profitability. It’s all about making small, incremental improvements to your products, services, or processes over time. Think of it like upgrading your business bit by bit, day by day. It’s like taking the stairs instead of waiting forever for a potentially broken elevator to reach your desired floor.

But why should you care? Well, it’s simple. Continuous improvement helps you stay competitive, keep your customers happier, and ultimately make your business more profitable. And who doesn’t love more profits?

The Magic Behind Continuous vs Continual Improvement

Now, you might be thinking, “But what about continual improvement? I’ve heard that term too. Is there a difference?” Well, you’ve got a keen eye there.

The terms ‘continuous improvement’ and ‘continual improvement’ are often used interchangeably, but they hold subtle differences. Continuous improvement refers to uninterrupted, ongoing improvements that are linear and incremental in nature. It’s like tuning a piano, constantly making minor tweaks to keep the music flowing beautifully.

On the other hand, continual improvement is broader. It encompasses continuous improvement but also includes improvements that might not be continuous or incremental. It’s like remodeling your house—you don’t do it every day, but when you do, it significantly enhances your living space.

Getting the hang of it? Now that we’ve cleared that up, you’re well on your way to understanding the ins and outs of improvement strategies that can fuel your business growth.

In the next section, we’ll dive into some tools and methodologies that can help implement continuous improvement in your business. So grab your notebook, and let’s get rolling. It’s time to awaken the continuous improvement guru within you.

The Power Tools of Continuous Improvement: Which One is Right for You?

Unmasking the Plan-Do-Check-Act (PDCA) Cycle

Ever wondered if there’s a straightforward, step-by-step approach to continuous improvement? Meet the Plan-Do-Check-Act (PDCA) cycle, often referred to as the Deming Cycle. Picture it as a compass guiding your business toward improvement.

- Plan: Identify an opportunity for change or a problem to solve. It’s akin to recognizing you have a rickety bridge in your town that needs fixing.

- Do: Implement the change on a small scale, like repairing a part of the bridge to test if the solution works.

- Check: Gather and analyze data to see if your change made a difference, like testing the strength and durability of the repaired section.

- Act: If the change worked, go ahead, roll it out wider. If it didn’t, it’s back to the drawing board.

With PDCA, you’re effectively running your business improvements like science experiments, using data and observations to guide your decision making.

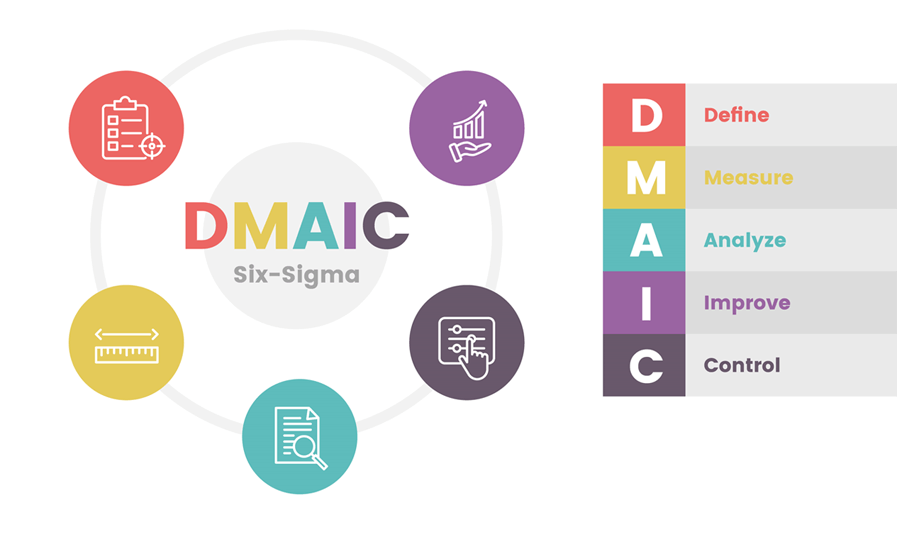

Six Sigma: More Than Just a Fancy Belt to Show Off

Six Sigma might sound like the latest fitness craze, but it’s a mighty fine approach for businesses looking to karate chop waste out of their operations. A brainchild of Motorola, Six Sigma helps reduce defects and variation in your processes.

Picture your business as a pizzeria. Using Six Sigma, you’d aim for almost all pizzas coming out of your oven to meet your high-quality standards. In the Six Sigma world, that translates to a whopping 99.99966% of your products being defect-free. Now that’s a whole lot of perfect pizzas!

Lean Methodology: Let’s Trim the Fat off Your Business Processes!

Lean methodology, as the name suggests, helps your business slim down its processes, stripping away any unnecessary steps. Originated from Toyota, it focuses on enhancing value for customers and getting rid of waste.

Think of it this way: If your business were a long, winding road trip, lean methodology would be like having a super-efficient GPS that removes all unnecessary detours and traffic jams, getting you to your destination quicker, cheaper, and easier.

Total Quality Management: Because Your Business Deserves the Best!

Enter Total Quality Management (TQM), your all-inclusive pass to improving all corners of your business. TQM isn’t just a tool or a methodology. It’s a philosophy that emphasizes that your quest for quality should be woven into every fiber of your organization.

From the CEO to the mailroom clerk, everyone participates in improving processes, products, and services. It’s like orchestrating a choir where each singer, no matter their role, contributes to a harmonious output, resulting in a melodious masterpiece of quality that resonates with your customers.

Navigating the world of continuous improvement can be daunting, but once you’ve found the right tools and methodologies that resonate with your business, it’s an exhilarating ride towards success. Up next, we’ll delve into some real-world examples of continuous improvement in action. Stay tuned. It’s about to get real.

III. Real-life Success Stories of Continuous Improvement: Let’s Get Inspired!

Story 1: Hitting the Six Sigma Mark in a Pizzeria

Remember the pizzeria metaphor? Well, it’s time to serve up a real slice of life. An actual pizza restaurant chain decided to embrace the Six Sigma way. Their goal? Make sure every pizza came out of the oven perfect for their hungry customers.

They identified the leading causes of ‘pizza defects,’ which ranged from incorrect toppings to undercooking. After implementing changes and training staff on new procedures, they noticed a significant reduction in pizza errors, resulting in happier customers and more sales. Quite the tasty victory, wouldn’t you agree?

Story 2: Going Lean in a Hospital Setting

Lean isn’t just for manufacturing businesses. A hospital decided to apply Lean principles to improve its patient discharge process, which was causing backlogs and disgruntled patients.

They identified wasteful steps in the process, such as unnecessary paperwork and approval levels. Streamlining these led to quicker discharge times, happier patients, and more efficient use of hospital beds. This proves that Lean can work its magic anywhere, even in the most unexpected places.

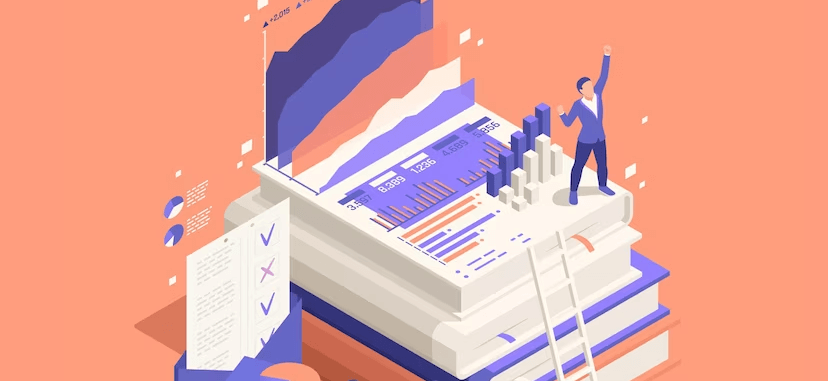

How to Implement Continuous Improvement: In 5 easy Steps

Feeling fired up and ready to go? Here’s a handy guide to get your continuous improvement journey started:

- Identify your Goals: Start by pinpointing what you want to improve. Is it reducing product defects, cutting costs, or perhaps speeding up a slow process? Be clear on your goals.

- Assemble your Team: Get the right people on board who are invested in this change. Remember, this includes everyone, from the top brass to the front-line workers.

- Select your Methodology: Will you go Lean, adopt Six Sigma, or perhaps embrace the PDCA cycle? Pick the one that aligns best with your goals and current situation.

- Plan and Implement Changes: Time to roll up those sleeves and get to work. Start small, and remember to track your progress.

- Review and Iterate: Gather data and see how your changes are performing. If something isn’t working, don’t be afraid to pivot and try something new.

Common Pitfalls in Continuous Improvement and How to Dodge Them

As with any journey, there are potholes on the road to continuous improvement. Here are some common pitfalls and how to dodge them:

- Not involving everyone: Continuous improvement isn’t just for the management team. Ensure everyone, at every level, is involved and feels a part of the process.

- Failing to communicate: Make sure everyone understands the why, the what, and the how of your continuous improvement efforts. Clear communication can’t be overstated.

- Overlooking data: Decisions should be data-driven. Remember, the ‘Check’ in the PDCA cycle? Make sure you’re gathering and analyzing data to guide your decisions.

- Resisting change: Change can be scary, but it’s necessary for improvement. Foster a culture where change isn’t just accepted, but embraced.

Continuous improvement is like setting off on a hike up a mountain. It might be tough, and you’ll likely face challenges along the way. But once you reach the peak, the view is absolutely worth it. So, are you ready to lace up those hiking boots and embark on your continuous improvement journey?

Continuous Improvement: Not Just a Trend, but a Lifestyle

You’ve probably noticed that continuous improvement isn’t some flash-in-the-pan trend. It’s here to stay. In fact, successful businesses aren’t just adopting continuous improvement—they’re living it. It’s becoming part of their DNA.

Think about companies like Amazon and Toyota. For them, the quest for better isn’t just a project or a department—it’s a way of life. It’s a constant, relentless pursuit that keeps them at the top of their game.

Amazon is famous for its ‘customer obsession,’ continually refining and enhancing its services to improve the customer experience. It’s not about one-off improvements but a commitment to an ongoing cycle of analyzing, refining, and enhancing.

Then there’s Toyota, the company that practically invented the concept of continuous improvement. Their Lean methodology, also known as the Toyota Production System, has been their mantra for decades. Toyota knows the race for improvement never ends—it’s the heart of their culture.

So, adopting continuous improvement isn’t just about gaining a competitive edge today. It’s about securing your place in the market of tomorrow.

Conclusion: Are you ready to Jump on the Continuous Improvement Bandwagon?

It’s time to ask yourself: Are you ready to embrace continuous improvement? Are you ready to start seeing ‘problems’ as opportunities for growth and innovation? Are you ready to foster a culture that’s committed to getting better every single day?

If you answered ‘yes’ to these questions, then you’re ready. You’re ready to start a journey that won’t just transform your business but will also set the tone for a culture of innovation and excellence.

So, lace up those shoes. Set your sights on that ever-evolving finish line. And remember: it’s not just about reaching a destination. It’s about embracing the journey—the journey of continuous improvement that leads to innovation, excellence, and a successful, thriving business.