Click the button to start reading

Grow A Successful Company Using Small Business Process Improvement

How do you make sure your company is the one that beats the competition? No one starts a business with the idea of folding in a few months. You want to be the one that gets a significant portion of the market and create something that lasts. Maybe you want to create a legacy or have something to give to your children.

If your company is going to be the one that thrives then it needs to be highly effective, respond to changes in the market, and offer a competitive and superior service. In order to do that, you should implement process improvements as the business grows and develops.

Processes are at the core of everything a business does, from shipping to employee onboarding. Everything needs to be workshopped and designed to be as effective as possible to cut costs, save time, and leave a better impression on the company. It doesn’t stop when you create the process, things need to be changed and adapted as time goes on.

Business Process Improvement (BPI) is something every leader needs to know about. So let’s take a look at what your small business has to do to stay competitive and relevant.

What Is Business Process Improvement?

In the simplest terms, business process improvement means optimizing your workflows to be as efficient as possible. Many things could prompt a review of processes such as complaints from customers or employees reporting inefficiencies. It may also be worth including a review annually to stay on top of things.

The review of your processes can uncover areas where the business is lacking somehow. This could be the result of modern technology outpacing the business and you will need to adopt these new methods to stay competitive. Alternatively, if your customer satisfaction is dipping, there will need to be changes made to raise this metric.

Identifying the problem areas is the first step in how to improve processes in business. Do this by listening to your employees and customers as they will be the first ones to notice any inefficiencies. Once you know what the problems are you can develop a plan to improve the processes which will bring things back up to company expectations.

It’s a methodology that requires business leaders to be open to changes and ready to adapt the business when necessary. Things can’t improve if you’re not willing to make the hard choices to switch things up. Doing something new in business can be frightful but business process improvement will lead to greater satisfaction, cut costs, and keep your company agile.

Why Is Small Business Process Improvement Important?

The business owner may have a lot of responsibilities that demand their attention. This is also the case if you have a small number of employees who need to juggle multiple roles to ensure business continuity. With extra roles on your plates, the best way to save time is by having finely tuned processes that can save time.

Small companies are usually in their growth phase which means they’re figuring things out as they go. At the start of their journey, processes are likely to be sloppy and undefined which can slow things down. However, as business owners and team members get more adept they’ll learn tricks to speed up their duties.

The business can assist its employees in this manner by focussing on small business process improvement. At this stage, it’s a good idea to have a round table with employees to discuss what’s going well and what hindrances exist in the business. Let the team lead by example and have them share any tips and tricks they have learned.

All employees have a duty to help improve processes in business. Given the opportunity to make suggestions, employees can offer up good ideas that the business owner may not have considered.

Business process improvement is a key ingredient for growth in the early stages of a company. By being open to refining your processes, you can ensure that your business stays agile and ahead of the competition. Companies that stay stuck in their ways can’t adapt to changes in technology and this will ultimately affect the bottom line.

7 Benefits of Small Business Improvement

It’s perfectly normal to feel attached to your current processes and shy away from the idea of change. After all, it will take time to learn new processes and it might upset your team if you have to change anything. People get stuck in their ways but this is bad for business.

If you need convincing that an annual review of your processes is necessary, let’s take a look at some of the best benefits of making improvements to processes in business. You can also use this list to talk your employees into new ideas if someone is apprehensive about proposed changes.

Prevents errors

Errors are bound to happen when a business is growing, it’s all part of the experience. The good thing is, when an error occurs, you can isolate what happened and make sure it doesn’t happen again. Whether it’s a human or mechanical error, the first time provides a unique learning opportunity for everyone involved.

Improves time frames

If your processes are improved they can save your team time to complete their tasks. This can affect the time frames you can offer your clients. A process change that saves 15% compared to the previous process increases output making your business more efficient. An annual review of processes ensures that your team stays at peak productivity.

Saves money

New processes can lead to savings on things like wages, wastage, direct, and indirect costs. The savings your business can make improve the bottom line and free up funds to be used in other areas. Saving money is always something business leaders should strive for. Business process improvements are one of the easiest ways to identify cost-saving opportunities.

Provides better value for customers

With improved time frames and money saved, you’ll be able to offer your customers better value. Keep ahead of your competition by staying efficient and working on the processes in your business. Secure your place as an industry leader by setting the standards on price and delivery times.

Increases profits

Profit is king. Every business wants to make as much profit as possible and any wasted money needs to be addressed. Reviewing your processes and implementing changes is a great way to increase your profits and will allow you to seek out additional clients or customers without increasing your overheads.

Improves communications

Inefficiencies in communication can hinder the progress of your projects and business. Communication improvements mean that employees can discuss in real-time and make decisions easily. Improving approval processes can also lead to better communication and get your team acting on things quicker.

Improves deliverables

The deliverables agreed with your client should be as efficient and effective as possible. With renewed processes, you can ensure the final product is going to impress everyone you deal with. Especially important for long-term contracts, if you can provide new products and services that your customers love, you’ll keep them around for a long time.

Common Small Business Process Improvements to Implement

There are plenty of different schools of thought to consider if you are looking for a way to improve processes in business. Methods like this have been designed to be incredibly effective and it’s worth considering which one is best for you. Some methods have been specifically designed for certain industries, while others can be used in all manner of businesses.

Here are 9 examples of methodologies you can apply to your company and improve your processes as your business develops.

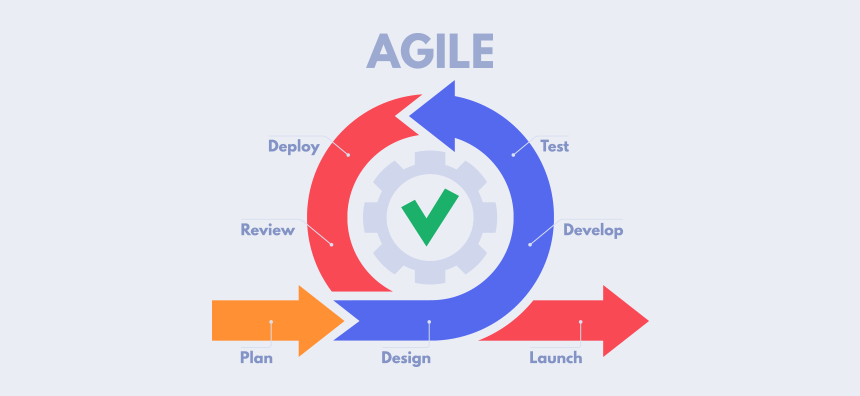

Agile Management

Agile is a methodology that takes an iterative approach to software development. You can also apply its principles to any kind of project management. Using an Agile method means breaking down projects into smaller sprints that last between 1-2 weeks. There is a reliance on meetings to continually improve processes and make the next sprint more effective.

Teams are led by a Scrum Master who will be responsible for ensuring that Agile methodology is being adhered to and answering any questions team members have. This method helps teams to provide value to their client while continuing to grow and adapt during development.

The method focuses on continually reviewing hindrances and efficiencies at the end of each sprint. Findings will then be implemented to the next sprint so teams can work more effectively towards their goal. The process is then repeated at the end of that sprint before the next one starts.

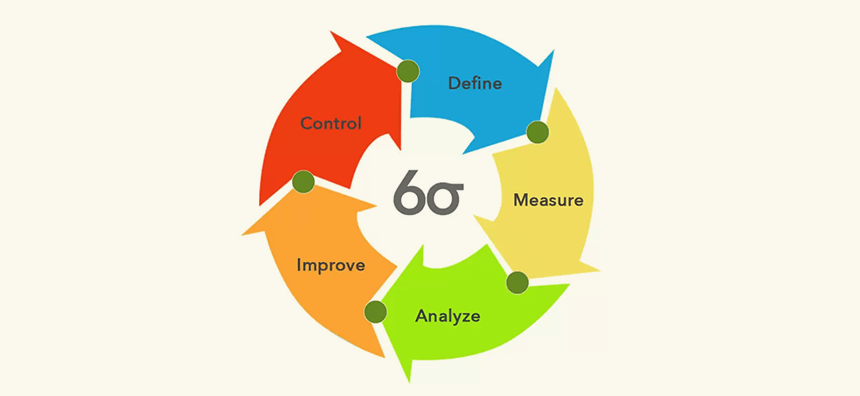

Six Sigma

Six Sigma is a method of decreasing variation in processes and creating greater process control. There is an additional method known as Lean Six Sigma which also focuses on eliminating non-value-added processes. Many aspects of each method can overlap and help your business to achieve better results.

If you want to focus on reducing variation within your processes then you will want to prioritize Six Sigma principles. For businesses who would like to assess their processes for waste, take a Lean approach to analyze the facts and data to improve customer satisfaction. The Lean method relies on the involvement of all your employees to work on process enhancement together.

The steps for implementing Six Sigma is known as DMAIC and they are:

- Define the problem: Create a statement of what the issues found are. You can do this by using a process map, customer requirements, or a goal statement.

- Measure the current process: Look at current performance data and any issues the team is facing. Identify any inefficiencies in the way things are done at the moment.

- Analyze what’s causing any issues: Compare the data and processes to investigate the cause of the issues and log your findings.

- Improve the processes: Now you need to workshop solutions for the issues that have been uncovered. Work out how to start implementing them to improve the efficiency of your processes.

- Control (and monitoring): Keep monitoring your new processes to ensure they are working out. Continue to refine if necessary while looking out for other areas of improvement within the business.

Lean Management

Lean management is a method of continuous improvement that takes the viewpoint of the customer into consideration. It’s a long-term approach that prioritizes smaller changes to your company’s processes to facilitate improvements in quality and productivity.

You’ll focus on what your customer demands are and work on optimizing your workflows to reflect this. There will be a focus on cutting out any wasted time and revising processes that are not creating good value for the business and its customers.

Shared leadership is required for this method and every employee will be expected to contribute and take ownership for productivity. The method is sometimes referred to as the Toyota way as it was developed by the company in the 1940s. There are 5 principles involved in this process which are:

- Identify value: Find the problem that faces your clients and how to properly serve a solution. Avoid adding processes that contribute to waste as the goal should be to eliminate this.

- Value stream mapping: Map out the workflows in place at your company including all contributors to the process and deliverables for your clients. This is a visualization tool that helps business leaders identify areas that aren’t providing value to the company.

- Create a continuous workflow: These workflows help to keep your teams on track and avoid any bottlenecks. One of the easiest and most effective ways to achieve this is by using Kanban boards as a visualization tool to aid communication and productivity.

- Establish a pull system: A pull system is a technique that helps leaders to identify waste within the production process. Use this method to ensure there is sufficient demand for projects and reduce your overheads.

- Facilitate continuous improvement: Monitor what your team has done and what still needs to be achieved. Since the Lean management process is not a one-and-done solution, you should aim to continually identify and improve any inefficiencies.

Kaizen

Kaizen is a methodology that originates from Japan which essentially means “change for better.” The way this method works is by incorporating gradual improvements to processes and asking all employees to be a part of it. There is a strong focus on creating a better team environment at work to promote employee engagement and be more fulfilling for team members.

There are a few key objectives you need to understand about Kaizen which are:

- Standardized work

- Just-in-time delivery

- Quality control

- Waste elimination

- Efficient equipment usage

- Employee stakeholders

- Viable solutions

Five tenets make up the Kaizen approach which aims to achieve good business practices, waste elimination, and standardization across the business. These tenets are teamwork, discipline, improvements to morale, quality, and open suggestions. Kaizen wants to ingrain continual improvement into company culture and bring out the best in every employee.

Making each employee a stakeholder in company improvement is a key element of this method. The Kaizen method understands that the most knowledgeable people in the company are the ones who are performing the tasks. Therefore, the best strategy to improve processes is by including them in the discussions.

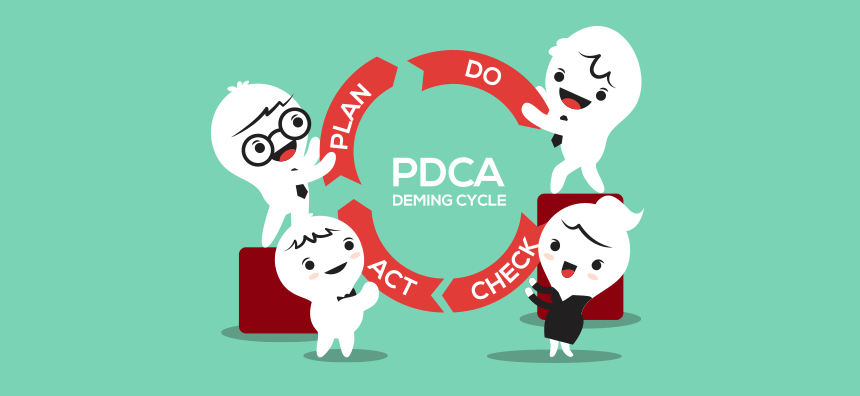

Plan-do-check-act (PDCA)

You may have also heard this referred to as the Shewhart Cycle. The PDCA method was created in the 1950s by Dr. William Edwards Deming. This method allows you to solve problems and create new solutions in a rigorously thought-out and methodical way. The process works well in all kinds of businesses and works by splitting processes down into smaller steps.

Let’s take a look at each of the 4 steps in greater detail.

Plan

The first step is to identify what’s not working, whether it is to do with customer satisfaction, deliverables being delayed, or something else. Explore any information available that can highlight what caused the problem.

Next, you’ll need to workshop new solutions to improve things on the next go around. As well, you should create a fine-tuned plan to implement these new ideas.

At this point, you should also list the criteria of success to be measured against in the third stage of this process.

Do

The next phase is implementing the changes. PDCA suggests that you start off with small-scale pilot projects that can be highly monitored and controlled to test the efficacy of new ideas.

By focussing on a smaller pilot project, businesses can test new ideas without causing disruption to the wider operational practices of the business. A good example of this is when you try out a new partner for something like deliveries.

If customers are reporting problems with one partner, the business can trial a new delivery team for a small portion of customers to see if opinions improve before rolling out the changes company-wide. The data collected during this period will inform if changes should be made.

Check

The check phase is where you compare the data collected and measured against the criteria of success you created as part of step 1. This is what will decide if the new ideas are a success or not.

If the results are not what you anticipated then you should return to step 1 (plan) and try something new. However, if the results worked out according to, or better than planned then you can move on to the final step in the PCDA process.

Act

This is the phase where your new idea is rolled out to replace the inefficient process. You’ve collected enough data to know that the new ideas are better and now is the time to introduce them across the company.

At this point, you establish a new baseline for your processes but the job isn’t done there. PDCA is intended to be used as a loop, so you should be prepared to review your processes again and iron out any new inefficiencies if they occur.

Poka-Yoke

Poka-Yoke is another Japanese methodology that loosely translates to “mistake-proofing.” It’s a process analysis tool that uses automatic devices to ensure mistakes can’t be made, or if they are, they’re immediately obvious. The focus is on eliminating human error within the team or preventing customers from making costly errors.

A great example of Poka-Yoke is driving a car with a manual gearbox. The mechanism won’t allow you to make a mistake because you will not be able to change gears without pressing down on the clutch first. Also, child-proofing techniques are another example of mistake-proofing.

Poka-Yoke focuses on preventing errors from occurring in the first instance. And when errors happen naturally, they will be immediately addressed and prevented from happening again in the future. Changes should be implemented whenever a mistake happens and Poka-Yoke can work in tandem with Six Sigma to ratify processes.

Monitoring and Control to Improve Processes in Business

The job doesn’t end after implementing new processes because things will always change. New technology could be released that can aid your business or new inefficiencies will be discovered. Once you have better processes in place you need to monitor them daily to ensure they are effective.

Speak with your team to make sure that the new ideas are working out well for them. They will be the first ones to uncover any issues and if they do, your job will be ironing them out to keep up productivity. The first few weeks of the rollout will be the most crucial for catching any developing issues.

Ask your team for feedback on the new processes and allow them the space, to be honest about things. Your team is the ones who will be dealing with changes on the ground level and will be the first people to know if things are working as effectively as expected.

The last thing to do is to roll your new processes into your annual review process. As a business leader, you will want to ensure you are providing exceptional work at an efficient work rate to keep providing your clients with value for money products.

Conclusion

Improving business processes is always a good idea. Allow your employees and customers the opportunity to discuss inefficiencies and work hard to remove them. If you’re not personally involved in the process it can be hard to know when things aren’t working.

Let your team guide you in the right direction by ensuring every employer is treated as a company stakeholder. What’s good for the company is good for the employees and the best ideas often come from the ground level.

Strive to create a business that can respond to adversity and changes swiftly and decisively. Consider which of the processes mentioned will work well for your business and build them into your business. This way you can stay competitive and always offer superior service.