Click the button to start reading

Six Sigma Simplified: Ditch the Waste and Streamline Your Projects

Efficiency is the name of the game in project management.

After all, if a project is taking too long, it’s likely going to cost more money than necessary. Six Sigma is a methodology that can help you streamline your projects and get them done faster – without sacrificing quality.

The name “Six Sigma” is a technical term that refers to a statistical measurement related to bell curves.

For the sake of article space, its statistical definition is unnecessary. Just know that the goal of Six Sigma is used to streamline your projects process so that there are as few defects as possible.

Or simply put: Six Sigma = no wasted time or resources.

Essentially, it’s about efficiency and quality. And who doesn’t want that?

The trouble with many project management processes is that they are bogged down with waste. This could be anything from inefficient communication to an unclear project scope.

Six Sigma seeks to identify and eliminate this waste so that projects can be completed faster and more efficiently.

The good news is that you don’t need a team of statisticians to implement Six Sigma in your project management process. In fact, it’s relatively simple to get started.

This article is all about the basics of Six Sigma and how you can use it to improve your project’s aims. Let’s get started!

What is Six Sigma?

As we mentioned, Six Sigma is a methodology that seeks to streamline a process so that there are as few defects as possible.

This might sound like a tall order, but it’s actually quite achievable. In fact, many companies have managed to achieve “Six Sigma” quality levels. This means that they have just 3.4 defects per million opportunities.

To put this into perspective, if a company has a process with 1 million opportunities for defects, Six Sigma would mean having just 34 defects. That’s a pretty low number!

It became popular in the 1980s as a way to improve manufacturing processes, but it has since been adopted in other industries as well.

These days, Six Sigma is used in project management as a way to streamline processes and achieve better results in less time.

6 Benefits of Six Sigma for Project Management

There are many benefits of Six Sigma for project management. Here are just a few:

1. Improved Quality Control

One of the biggest benefits of Six Sigma is that it can help you improve the quality of your products and services.

By identifying and eliminating defects, you can ensure that your customers are always getting the best possible experience.

By vigilantly examining quality, you can often recognize problems as they start and take care of them before they grow into something much more serious.

2. Increased Efficiency

Another big benefit of Six Sigma is that it can help you increase the efficiency of your processes.

By streamlining your process and eliminating waste, you can get your projects done faster and with fewer resources. This will reduce cycle times and save you money in the long run.

This is good news for both your bottom line and your team’s morale.

3. Improved Customer Satisfaction

Ultimately, all businesses exist to serve their customers.

By implementing it, you can improve customer satisfaction by ensuring that they always receive high-quality products and services.

Plus, by reducing cycle times and increasing efficiency, you can also improve their experience by getting them the results they need faster, resulting in a happier customer.

And you know what that means… happier customers are loyal customers.

4. Better Understanding of What Customers Want

In order to provide the best possible experience for your customers, you need to have a good understanding of what they want.

This is exactly what Six Sigma can help you with.

The data collected during the Six Sigma process can give you valuable insights into your customers’ needs and desires. This, in turn, will allow you to tailor your products and services to better meet their needs.

5. Increased profitability

When processes are dialed in and running smoothly, it frees up time and resources that can be used to generate revenue.

In other words, when your projects are running efficiently, it can actually lead to increased savings.

Ultimately, these savings can lead to increased profitability for your business.

6. Improved morale

When your company and team are performing well, it can lead to an improved morale.

Your team will be more engaged and motivated if they feel like they’re part of a successful organization. This, in turn, can lead to even better performance and results.

In addition, by providing training and opportunities for employee development, Six Sigma can help attract and retain top talent.

It’s a positive feedback loop that starts with Six Sigma.

Nuts & Bolts of Six Sigma – How it works

Now that we’ve covered some of the benefits of Six Sigma, let’s take a look at how it actually works. There’s a standard set of steps that are followed in order to Six Sigma a process.

We could debate the exact order of these steps, or whether some steps are more important than others. But at a high level, this is are the steps:

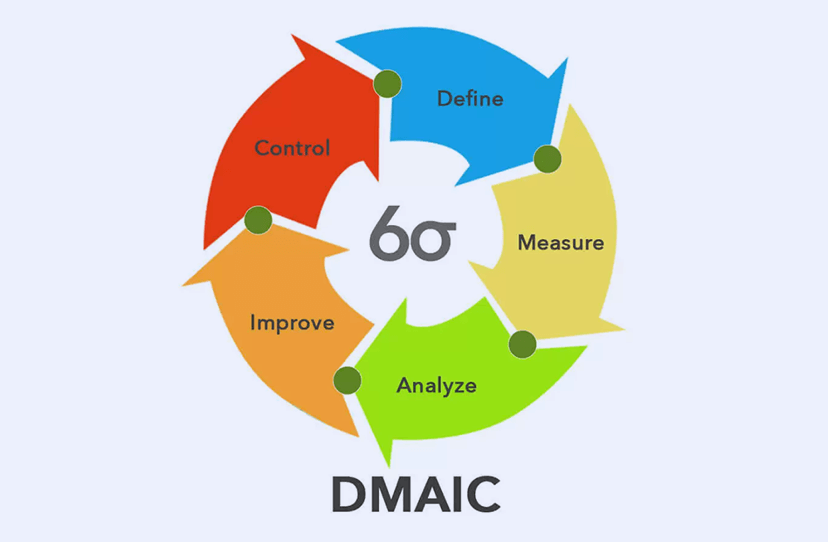

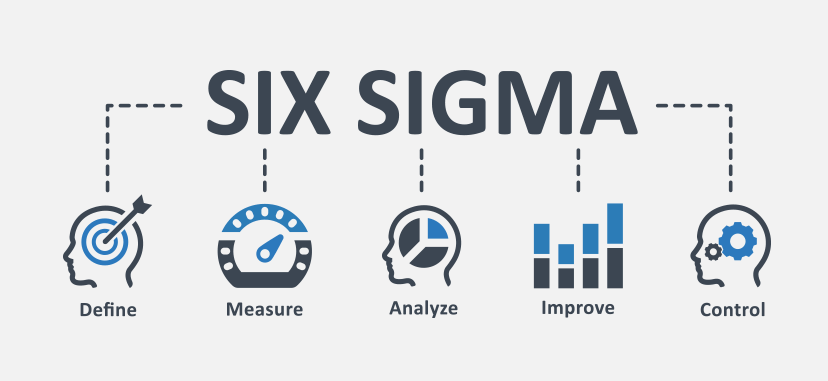

- Define

- Measure

- Analyze

- Improve

- Control

Let’s take a closer look:

Define

The first step is to define the problem that you want to solve.

This might involve identifying a specific issue that you want to address, such as reducing cycle times or increasing throughput. Once you’ve defined the problem, you need to set measurable goals so that you can track your progress.

Measure

The next step is to measure the current state of your process.

This will involve collecting data so that you can identify where there are issues. In addition, you need to establish baseline metrics so that you can track your progress over time.

Analyze

Once you’ve collected data, it’s time to analyze it so that you can identify the root cause of the problem.

This might involve using statistical tools to identify patterns or trends. In addition, you need to make sure that you understand the impact of any potential solutions.

Improve

Once you’ve identified the root cause of the problem, it’s time to develop and implement a solution.

This might involve changing the way your process is designed or introducing new methods or technologies. In addition, you need to make sure that the solution is effective and does not create any new problems.

Control

The final step is to control the process so that the problem does not recur.

This might involve puttiing in place new procedures or controls. In addition, you need to monitor the process on an ongoing basis to make sure that it is running smoothly.

By following these steps, you can Six Sigma any process so that it runs more efficiently and effectively.

Six Sigma in Project Management

Now that we’ve covered the basics of Six Sigma, let’s take a look at how it can be used in project management.

Lean Six Sigma

Six Sigma has a long history of promoting collaboration among teams, going all the way back to when it was first developed into Lean Six Sigma in the early 2000’s.

The main idea was to take the best of both Six Sigma (the focus on quality and efficiency) and Lean manufacturing (the focus on reducing waste), and combine them into one powerful methodology.

The result was Lean Six Sigma, a methodology that has since been adopted by many organizations, in a variety of sectors around the world.

When it comes to project management, Lean Six Sigma can be used to improve the efficiency and quality of any project.

Agile Six Sigma

Agile is a popular methodology that focuses on delivering value early and often, through short iterations known as sprints. The main hallmark of Agile is its emphasis on collaboration and constant feedback.

In recent years, there has been a growing trend of combining Agile and Six Sigma into what is known as Agile Six Sigma.

Agile Six Sigma takes the best of both worlds, combining the focus on quality and efficiency of Six Sigma with the flexibility and collaboration of Agile.

How to use Six Sigma in your project management

If you’re a project manager, you might be hesitant to tamper with something that’s already in motion and working well. After all, the last thing you want is to rock the boat and end up with a bigger mess on your hands.

But the truth is you’re probably already using Six Sigma in your project management, whether you realize it or not. In fact, many of the tools and techniques that are used in Six Sigma, such as process mapping and root cause analysis, are also used in project management.

The difference is that in project management, these tools and techniques are used to manage the project, rather than the process.

So how can you use Six Sigma in your project management? Here are a few ideas:

- Use process mapping to understand the project and identify potential areas of improvement.

- Use root cause analysis to identify the underlying causes of problems so that they can be addressed at the source.

- Use statistical tools to analyze data and identify patterns or trends.

- Use process improvement techniques to develop and implement solutions that will improve the efficiency and quality of the project.

- Control the project so that problems do not recur.

By using these tools and techniques, you can Six Sigma your project management and make your projects more efficient and effective.

Understanding the Limits

Just like any other tool or methodology, Six Sigma has its limitations.

One of the biggest limitations is that it can be complex and time-consuming to implement. In order to get the most out of Six Sigma, you need to have a clear understanding of the tools and techniques involved.

You also need to be able to dedicate the time and resources necessary to implement it properly. If you try to shortcut the process, you will not get the desired results.

Another limitation of Six Sigma is that it is not always well-suited for small projects. The tools and techniques involved are designed for large, complex projects.

If you try to apply them to a small project, you may find that it is more trouble than it’s worth. In some cases, it may be better to use a different methodology, such as Agile or Scrum.

Finally, Six Sigma is not a magic bullet. It will not solve all of your problems or make your projects perfect.

It is a powerful tool that can help you to improve the efficiency and quality of your projects, but it is not perfect.

When used correctly, Six Sigma can be a valuable addition to your project management toolbox. Just be sure to understand its limitations before you try to implement it.

Conclusion

When Motorola developed Six Sigma in the 1980s, it was a revolutionary new approach to quality control. Since then, Six Sigma has been adopted by many organizations around the world and has become an essential part of project management.

Why? Because the framework works. It’s been proven to improve the quality and efficiency of projects, time after time.

So if you’re looking for a way to take your project management to the next level, consider using Six Sigma. It just might be the answer you’ve been looking for.