Click the button to start reading

Finding Metrics With Meaning: How to Measure Productivity In the Workplace

We’ve all seen productivity metrics that don’t make any sense. Why is the employee who goofs off every afternoon consistently out beating the rest of the team in sales? And why is customer feedback declining at the same time that revenue is increasing?

When it comes to evaluating productivity, it’s easy to churn out all sorts of reports, evaluating things like customer retention, production times and ROI for material and labor. But it’s much harder to pinpoint the values that really matter.

Productivity is a multi-faced topic. Improving productivity is rarely so simple as removing the cog in the wheel or fixing the bottleneck in the assembly line, then calling it a day. If only. More often than not, low productivity stems from larger systemic issues than an employee who loafs or technology that’s outdated.

And so meaningfully evaluating productivity means looking at the big picture before plugging numbers into equations. It means knowing the overall objectives, and then filtering the factors that really drive productivity from those that don’t really matter. The meaningful metrics aren’t always the most obvious ones. And the right metrics for one industry aren’t the same as those for another.

Lest these complications leave you pulling out your hair, let’s dig further into this topic, first by reviewing how to calculate productivity, then considering approaches to measuring employee productivity within your organization.

Productivity Calculation With Examples

Productivity is a measure of efficiency. It’s a concept we refer to all the time, when we talk about things like how many miles a car gets for each gallon of gas, and how much we can produce in an hour of work.

Simply put, productivity measures the level of output for a given level of input. The productivity calculation is quite simple.

Productivity = Measure of output/Measure of input.

This equation is applied in a variety of ways. Input can be anything from time to materials to labor. And output can measure a range of values as well. It can represent the revenue or profit for a company, the number of units produced, or even the number of hits a website receives.

This equation is used to calculate the GDP for a country, the labor productivity for an organization, the fruits of a marketing campaign, and things like customer retention and customer satisfaction.

Most organizations have multiple ways to evaluate productivity. For this reason, the productivity equation is modified to calculate several different values. This modification includes single factor, multi factor, and total productivity.

- Single Factor Productivity, also known as partial productivity (PPM), evaluates output relative to isolated inputs, such as labor and raw materials. Labor productivity, for example, calculates output/human input, whereas capital productivity calculates output/capital.

- MultiFactor Productivity, on the other hand, incorporates multiple factors into the productivity equation. For example, it might measure output in terms of both labor and materials, where Productivity = output/(labor and materials).

- And finally, Total Productivity (TPM) measures output in terms of the sum of all of input, such as labor, materials, energy and capital. TPM = output/(labor + materials + energy + capital)

Various Applications of Productivity

Although the productivity calculation is fairly simple, its application is varied and can be complex. It’s most commonly used to evaluate efficiency, and so calculates output in terms of labor. It is also applied to calculate output in terms of materials used and capital invested.

However, as discussed, many other variables outside of efficiency determine the success of an organization. These variables may be applied to the productivity equation as well. For example, an employee’s level of education and training might impact output, and so “education” or “training” can be used as an input. Additionally, factors such as quality, innovation, customer service, and even marketing can also be used to measure productivity.

The key is to find a meaningful metric to quantify each of these variables. “Education” may be measured in the number of training hours, quality can be measured in the number of errors per batch and customer service in things like the retention rate or the resolution rate (in a call center). The productivity of a marketing campaign could be measured in the number of hits to a website per advertising dollars spent.

Now let’s look at how to calculate productivity in various contexts.

Examples of Productivity Calculations

In a productivity calculation, a higher number is better than lower number, as it indicates more units of output per unit of input.

Labor in a Firm

Let’s start with a very simple example of a firm with 20 employees that earns a revenue of $2,000 on average each day. The labor productivity for this firm equals its output divided by the input. This is $2,000/20, or $200 per employee per day.

This same calculation can be modified to calculate the productivity per hour. Assuming each employee works for 8 hours per day, the input becomes 20 employees multiplied by 8, or 160 hours per day. As output remains the same, the labor productivity per employee per hour equals $2,000/160, or $12.50.

Housekeeping in a Hotel

Now let’s consider the productivity of housekeeping in a hotel. In this instance, productivity is measured not in dollars, but in the number of rooms cleaned.

Let’s say a team of ten employees cleans 500 rooms per week. The output is the number of rooms cleaned, and the input is the number of employees.

500 rooms/10 employees = 50 rooms cleaned per employee per week.

Widgets in a Factory

And finally, let’s look at an example of a factory that produces widgets, where output is measured in widgets produced.

In this factory, one employee produces an average of 16 widgets in 8 hours. Here the output is 16, and the input is 8 hours. 16/8 = 2 widgets per employee per hour.

Guidelines for Calculating Productivity

In order for the productivity metrics to be meaningful, it’s good to follow a few guidelines.

Use Benchmarks

It’s pretty easy to calculate productivity, but generally, the value is meaningless unless it can be measured up against something else. Benchmarks serve to determine whether productivity is increasing or decreasing with relation to time, investment, training, or any other relevant factor.

For example, maybe a factory calculates that one employee produces about 200 widgets per day, and it establishes this as a benchmark. Next, it provides efficiency training to half of the workforce. Afterwards, the portion of employees who received training increased daily production to 225 widgets, while the production of the untrained portion remained the same.

Establishing a benchmark makes it easy for the company to determine that the training is effective in increasing productivity. Sometimes it’s also helpful to use industry standards as benchmarks, to see how a company measures up against the competition.

Compare Apples to Apples

When calculating productivity, it’s important to use consistent units. For example, if most of the productivity is measured in labor hours, then it isn’t helpful to run calculations for daily labor.

And while productivity can be measured in a variety of ways, in order for benchmarks to be useful, it’s necessary to pick one approach and stick to it for a time. That is to say, it isn’t helpful to measure the widgets produced per hour for one quarter, then switch things up the next quarter and start looking at the revenue earned per employee per day.

Use Relevant Data for the Industry

Meaningful productivity metrics vary widely depending on the industry. In a service industry, for example, customer feedback is a significant factor that impacts productivity. While in the transportation industry, the number of damaged packages per delivery might be a much more relevant productivity metric. And so it’s important to consider industry standards when calculating productivity for your organization.

With these basics under our belt, let’s look into some methods for measuring employee productivity within an organization.

6 Ways to Measure Employee Productivity

As previously stated, meaningfully assessing and improving productivity requires thought and analysis. It’s not so simple as increasing output, full stop. For example, say a factory increases its rate of production but in doing so it compromises on quality. It’s quite likely then that the overall revenue for the organization would decline, which certainly isn’t the objective for any organization. Furthermore, it’s always tempting to throw technology at a productivity issue and assume that will solve the problem. But this isn’t necessarily the case. Without training or proper rollout, big system overhauls may well encounter resistance to change.

All this is to say that more fundamentally, before measuring and evaluating employee productivity, it’s necessary first to consider the organization’s overall objectives, as well as the implications any productivity measures might have on the company culture. Once those issues are addressed, then it’s possible to measure employee productivity in such a way that it works toward the overall mission of the company.

And fortunately, there are plenty of tried and true methods for evaluating the productivity of both individual employees and teams. Let’s briefly review six of them.

Track Attendance and Participation

If an employee never shows up in person to the office and rarely attends meetings, it may well mean that he or she isn’t helping to boost the bottom line. Attendance and participation can be measured in a number of ways, depending on the industry and the nature of the work. Once a system is established that routinely tracks overall involvement, it’s possible to distinguish those employees who have their head in the game from those who have their head in the clouds.

Measure Errors and Defects

Errors and defects translate into either rework or a substandard product, which ultimately means time and money down the drain. Within some industries in particular, tracking things like errors and defects meaningfully assesses an employee’s level of productivity. In software, for example, too many defects may mean that the team needs to run a hardening sprint, which lowers its overall velocity. And in the trucking business, damaged materials means too many returned items, which is a huge drain on resources.

Break Things Down

It’s easy to look at an entire workforce as one huge monolith. However, breaking things down into increasing finer detail makes it possible to measure both individual and team output, and in doing so identify issues and leaks.

Take a hotel housekeeping staff that is separated into five teams. Let’s say that overall, the staff cleans 500 rooms per week. On average, then, this is a productivity level of 100 rooms cleaned per team per week (500/5).

However, breaking this number down may reveal some red flags. Maybe one team is only really cleaning 75 rooms each week, while another team is making up for them by cleaning 125. Addressing productivity issues means looking closer at the low productivity team. It might mean calculating the rooms cleaned per each individual on the team, or looking at the management method the team uses.

360 Degree Feedback Method

Every individual brings a valuable perspective to an organization, regardless of his or her rank or title. And an organization concerned about employee productivity may well benefit from gleaning some of this insight.

A system of gathering feedback on employee performance from everyone in the organization offers unique insight that might not be gained from any other performance method. It identifies those employees who have high regard and rapport amongst their peers, as well as those employees who create division and factions within the company, both of which are key factors in productivity.

The one drawback to implementing this method is that it could lead to pitting employees against one another, which is one of the fastest ways to destroy rapport and create a toxic culture. And so it needs to be rolled out and conducted with caution.

Calculate Employee ROI

Some positions receive a small compensation relative to the value they bring to the organization, whereas others demand a hefty salary while adding nearly the same value.

Weighting the company’s overall revenue alongside the employees salary indicates how much they bring in, versus how much they cost the company. Making this value meaningful may mean breaking overall revenue down into individual projects, then measuring an employee’s return based on the projects he or she participated in.

Using this metric is a delicate dance, however, as employees prefer to be treated as stakeholders rather than assets. Evaluating an employee based on their ROI makes employees feel like “just a number” and it may lead to turnover.

Set Benchmarks and Targets

Again, productivity metrics are useful when weighed against other criteria. Identifying the current state (the benchmark) and then a desired objective (target) is one way to measure employee productivity.

For example, if employees currently produce three widgets per day, set a benchmark to increase the number to four over a quarter. Then evaluate which employees reached the target, and identify why. Maybe the employees who received additional training and equipment were more likely to increase production over those who didn’t receive any special treatment.

And this summarizes a few methods. Measuring employee productivity is an ongoing process with several distinct stages. In addition to measuring, it’s necessary to then improve methods through trial and error. And oftentimes larger variables come into play that impact employee productivity, including things like the company’s culture and its policies around well being.

6 Tips & Strategies to Boost Productivity

As stated, productivity is a multi-faced topic, and many variables contribute to the overall productivity of an organization. And no organization is ever “there” with respect to productivity. It is an ongoing process. To this end, let’s look at some tactics to help achieve productivity objectives within an organization.

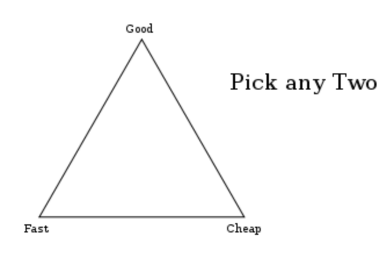

Orient Metrics Around the Objective

As previously discussed, simply speeding up production times doesn’t always lead a company to a better place. As the “good, cheap, fast” triangle shows, focusing in on one area means losing out on another. Making production faster either means increasing cost or decreasing quality.

And so before making any improvements, it’s necessary to take a step back and look at the overall objectives. If the company cannot compromise on quality, then it makes sense to establish productivity metrics that measure quality rather than speed.

Manage Capacity to Avert Waste and Burnout

A productive workforce isn’t a place where every employee works at 100% all the time. Capacity planning carefully evaluates the systems in an organization to create workflows that maximize productivity. And in order to accomplish this, it utilizes things like protective and idle capacity. Sometimes, this means hiring above and beyond what the regular capacity demands.

For example, maybe a restaurant normally serves about thirty customers an hour, but in the afternoons it receives a sudden rush of 80 to 100 customers who want to be served right away. Maximizing sales (output) during this rush period means having enough staff on hand to serve them all. Even if it means that many of the employees stand around during the other parts of the day, this protective measure increases productivity in the long haul.

At the other extreme, hiring below capacity and forcing employees to work themselves to the bone may well lead to burnout and high turnover rates.

Focus on the Organizational Structure

Sometimes it happens that one team in an organization consistently produces great products, while another team’s output is consistently lackluster. How to account for this disparity? Of course, it may simply come down to factors like talent and hard work, where one team may out measure the other on both counts. However, organizational structure is just as likely to account for the disparity.

Conway’s Law is a principle that says that an organization’s output is a mirror of its organizational structure. A team with a rigid chain of command, for example, may not create as many innovative products as a team that emphasizes personal autonomy and intrinsic motivation.

And so improving productivity may entail studying an organization’s entire structure, and various smaller structures within it, to establish a system that replicates the output you want. Maybe a decentralized structure makes more sense, or a more top-down centralized structure, or something in between.

Realign and Reflect

Although it may seem counterintuitive, chugging along at full speed, day-in and day-out isn’t always the most productive system for an organization. Because if the organization is headed in the wrong direction, ultimately all this chugging just means a whole lot of rework.

Oftentimes the most productive system slow downs, or even comes to a full stop, after an intense period of work. Then it takes a moment of respite to reflect. At this time, it considers the overall objectives, and considers whether its current direction aligns with these objectives. It realigns and pivots if necessary. Then when everything is properly in tune and all systems are go, it resumes another batch of work.

Use Strategic Agility

Productivity and innovation go hand in hand. When an organization is capable of change, it can tweak systems, improve processes and implement new strategies.

However, oftentimes a system establishes deep grooves and people become rigid and set in their ways. In these instances, the system cannot implement any changes to keep abreast with changing times. Or else an organization might have a few employees who perform several essential tasks, but none of their processes are documented. And so when these employees decide to move on, the entire system falls apart like a house of cards.

Strategic Agility refers to an organization’s capacity to adapt and innovate. This includes documenting procedures and systems, so that knowledge is retained within the organization, and not simply with a few individuals. This fluidity within a system allows for experimentation, which is central to improving productivity. For example, a software team might implement the practice of pairing, to see if it improves overall output and quality.

Allocate Deep Focus Time

Every single day has its fair share of meetings, appointments, emails and people to call. However, it’s easy to get to a point where the workday consists entirely of this type of work. And a state of constant busyness and multitasking precludes the quality, focused work necessary to a productive organization.

Generally, work can be divided into two categories: operational and deep work. And when a company structures its workdays to allocate time for each, it creates the possibility for creative, high quality work.

One method that’s effective for creating deep focus is time blocking. This is when certain periods of time, either a portion of one day, or one day in the entire week, is dedicated to a specific task. For example, an office might dedicate Thursdays to deep focus work, and during this time no meetings are scheduled and it’s ok for employees to turn off notifications.

These tips should help to improve productivity within any system. And for any company looking to improve overall productivity, there’s several established systems and methods that promise to do just that. Let’s look into those next.

5 Productivity Systems for Optimum Output

Productivity may just as likely be a systemic problem as an employee or morale issue. Take, for example, a cafe that receives consistently poor reviews. One might assume that this is due to a lazy staff. However, the real cause might just as likely be a workflow that is full of bottlenecks and chronic delays. In this instance, then, improving productivity has more to do with fixing the system than changing the staff.

Over the past several decades, many productivity experts have come up with various systems and methods designed to improve productivity. Each offers particular strengths for particular circumstances. Let’s go over a few.

Theory of Constraints

Eli Goldratt developed the theory of constraints back in the 80s. Although initially he applied it to manufacturing organizations, he has written that principle can be applied into any scenario with a workflow, including service organizations and even home management.

His theory creates efficiencies within workflows and aligns work to the company’s overall objective. It does this by focusing on bottlenecks within workflows, and building systems around the slowest point in the process. Take a coffee shop for example. Maybe overall the workflow runs smoothly (supplies are delivered one time, orders are received), except that the coffees take a long time to make, forcing hurried customers to wait on their orders.

The theory of constraint focuses on this bottleneck. It fixes it by increasing the resources at this stage. This might mean hiring an additional employee to make coffees, or supplying the shop with an additional latte machine.

Kanban

Kanban is a productivity system based on the lean manufacturing principles at Toyota. Kanban creates a pull workflow by limiting work-in-process items. In order to move a task along the workflow and introduce new work items, teams swarm around it to bring it to completion. Kanban, then, increases collaboration amongst teams and it also reduces a tendency to procrastinate and put tasks off until the last minute.

Agile and Scrum

Agile is a product management system that developed in the 90s along with its counterpart, scrum. Although they originated in the software industry, both methods can be applied to almost any workplace. These methods seek to improve the final deliverable by working in increments and continually communicating with the client.

Agile arranges organizations into small autonomous teams who communicate daily, and who complete work in small batches. The teams regularly come together to evaluate its progress, and to realign upcoming tasks around the overall goal. Both agile and scrum empowers individuals, which fosters innovation. Their emphasis on continuous reflection also eliminates rework.

Waterfall

Waterfall is a more traditional and fixed approach to project planning that is helpful in any project that has large upfront costs. It utilizes Gantt charts and carefully plots out all the stages of a project from the start. Waterfall improves productivity in a project because it carefully plans a project out from start to finish, and addresses possible hazards and snafus before execution.

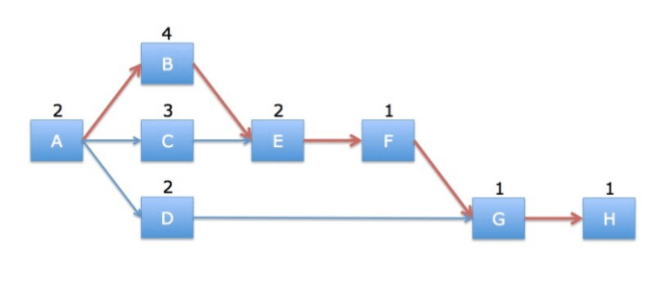

Critical Chain Method

The Critical Chain Method was developed in the 1950s by an internal think tank at DuPont. This method is helpful not only to estimate the duration of a project, but it also can increase productivity by identifying ways to speed things up.

This method uses a work breakdown structure to identify all of the small tasks required to meet a project’s high level requirements. Then, it arranges these tasks in a network diagram, identifying the sequence and dependencies between the tasks. Once it identifies the critical path in the network diagram, it can apply techniques such as crashing and fast tracking to speed up the project and distribute labor evenly.

Conclusion

Perhaps by now it’s a cliche to use the phrase “work smart, not hard.” But anyway, this is the key principle to apply when evaluating productivity.

Bigger, faster, and innovative technology aren’t necessarily the solutions to improving employee productivity. Rather, taking a step back and carefully evaluating systems and methodologies, as well as things like company culture, can have a much larger impact on an organization’s overall productivity.

However, measuring an employee’s productivity is an essential component to running a successful organization. And fortunately there are several methods that serve to do this. These techniques include things like counting defects, measuring participation and attendance, and gathering feedback from other employees.

Meaningful productivity metrics vary by industry. In some organizations, measuring employee productivity is as simple as counting how many widgets they produce in a day. While in others, productivity is more of an amalgamation of how much money they bring in, their customer feedback score, and their participation and attendance rate.

In addition to employee productivity, some of the handy tips to increase productivity include things like capacity planning and time blocking.

We hope this assists you in improving the productivity of your workforce. What’s the most significant measure of productivity in your industry?