Click the button to start reading

Why You Need to Consider Lead Time And Cycle Time For Your Project Management Strategy. Plus, 10 Tips to Reduce Your Project’s Lead And Cycle Times.

“Time is money,” right?

When it comes to business, this adage couldn’t be more true. And that’s why if you are a business owner or a project manager, understanding the core concepts of time measurement is essential.

In project management, two terms you’ll hear constantly are “cycle time” and “lead time.” What do they mean and how can you use them to your advantage? Read on to find out!

The terms Cycle Time and Lead Time are frequently used interchangeably in the manufacturing industry. However, there are significant distinctions between how they’re measured and calculated. Understanding how each of these is utilized may help your organization optimize operations’ workflow, resources, and labor time.

In this post, we’ll go through the various distinctions between lead time and cycle time. Then we’ll show you how to use each indicator to your advantage.

What is Lead Time?

Lead Time (LT) is the time it takes between placing an order and receiving it. This metric is important because it tells you how long it will take for your overall project to be completed in full.

LT represents the total time that you added to the project.

What is Cycle Time?

Cycle Time (CT) is the time it takes your team to complete an item, up until the product is ready for shipment. It’s the time it takes to complete one task.

In a manufacturing setting, the CT would be the amount of time it takes for a product to go from start to finish. This is an important metric because it tells you how quickly you’re completing your production.

The goal is to have a short cycle time so that you can turn around products faster and make more money.

CT represents the amount of time for which you’re working on a project.

Now that we’ve gone over the basics of lead time and cycle time, let’s take a look at the key distinctions between the two metrics.

The Difference Between Lead Time and Cycle Time

The distinctions between CT and LT are straightforward to grasp.

CT is a component of the overall LT, and it just assesses the production rate of the manufacturing process.

While Lead Time includes all operational procedures that precede and follow the manufacturing phase, Cycle Time only measures production rates in the manufacturing process.

The measurement of lead time is from the customer’s viewpoint, whereas the measurement of cycle time is from the internal process perspective.

EXAMPLE

Let’s say you are at a restaurant and you’re ordering food.

The LT would be the measurement of how long it takes for you to place your order with the waiter until the food arrives at your table. The CT would be the measurement of how long it takes for the cooks to receive your order until it’s cooked and delivered to you.

LT is important because you need to know how long it will take you to deliver the product. CT is important because you need to know how long it will take you to make the product.

If you have a long cycle time, it means that it takes you a long time to make each product. This can be costly and cause you to lose money.

It’s important to keep track of both lead time and cycle time so that you can optimize your manufacturing process and make the most profit.

Calculating lead time and cycle time:

How to calculate LT

To calculate the LT, you just need to know when the order was placed and when the client received the requested items. It’s the time it takes from receiving an order until it is sent out.

For example, let’s say you sell teeshirts, and a customer orders 5 teeshirts on Tuesday. The order is received on the following Monday. In this case, the lead time would be 6 days.

All the time spent in between these six days, from order processing to manufacturing to labeling to delivery, is accounted for when calculating Lead Time.

How to calculate CT

To calculate CT, you need to know when the teeshirt production started, and when it was completed. It is the time it takes from starting to work on an order until it is shipped out.

For example, let’s say it takes 12 hours to print the 5 teeshirts ordered by the customer. In this case, the cycle time would be 12 hours.

If you’re looking to improve your operations, it’s important to track and measure both Lead Time and Cycle Time. By doing so, you can identify areas where you need to make changes and improve your process.

Tips for improving LT and CT.

There are several methods to use cycle and lead time analysis to shed light on how you may improve business procedures. The nicest thing is that you don’t need to be a mathematician to make good use of cycle and lead time analysis.

There are a few things you can do to help improve your Lead Time and Cycle Time.

1. Improve communication between departments:

It’s very easy for time to be lost when departments are not communicating with each other. By improving communication, you can help reduce the amount of time wasted and make sure everyone is on the same page.

Communication flow can be guaranteed by creating a communication plan and following it religiously. Just make sure you allow time for regular check-ins between departments so you can ensure things are running smoothly.

2. Map out your process:

Mapping out your process can help you see where there are bottlenecks and where time is being wasted. You can also use this information to come up with ideas on how to optimize your process.

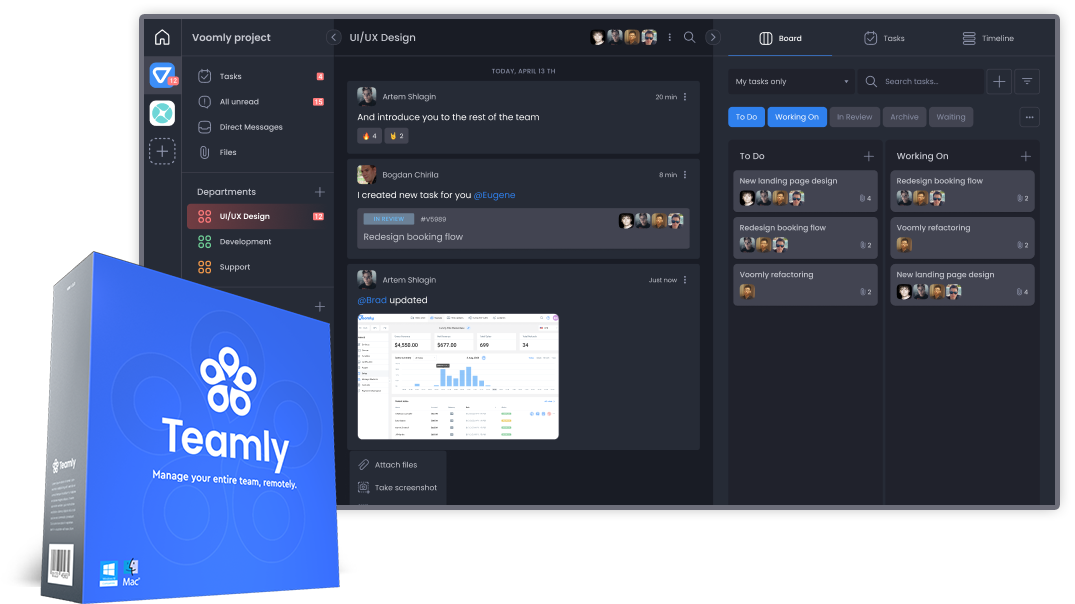

3. Invest in project management software:

Project management software can help you keep track of deadlines, tasks, and progress. This will help to prevent any overlap or missed deadlines.

And there is no better software than Teamly. Teamly allows you to manage your entire team, remotely. You’ll have the single project management software you need to finish tasks more quickly and effectively, giving you a distinct edge over your competition.

4. Fixing the bottlenecks:

Identify where things are taking too long and find ways to improve those areas.

Once you’ve mapped out your process and have identified the bottlenecks, it’s time to find solutions. This may require some trial and error, but by finding and fixing the bottlenecks, you can reduce the amount of time it takes to produce a product.

5. Simplify the process:

The more complicated the process is, the longer it will take. Find ways to streamline the process so that it’s more efficient. Delegate tasks, get rid of unnecessary steps, and make things as simple as possible.

7. Training and standardization:

Make sure all employees are properly trained and that the process is standardized. This will help to ensure everyone is doing things the same way, which will help to reduce the amount of time it takes to complete a task.

8. Use checklists:

A checklist can be an extremely valuable tool when it comes to reducing Lead Time and Cycle Time. By having a checklist, employees can make sure they are completing all the necessary steps, which will help to eliminate any wasted time.

9. Automation:

Automating tasks can help reduce the amount of time it takes to complete them. If there is a task that can be automated, explore ways to do so. This will free up employees to focus on other tasks, which will help to improve efficiency.

10. Incentivize employees:

Offer incentives to employees who complete tasks quickly and efficiently. This will motivate employees to work faster and more efficiently.

Conclusion

Although lead time and cycle time are often used interchangeably, they have different meanings and implications for your business. By understanding the pros and cons of each and employing the 10 tips in this article, you can reduce the amount of time it takes to get your product from inception to delivery.